Transform Efficiency

TRANSFORM

EFFICIENCY

WITH A NEWLY DEVELOPED 9-TON RUNNING GEAR, BPW IS HELPING LIGHTEN THE WEIGHT OF HEAVY GOODS VEHICLES. THE RESULT IS AN INCREASED PAYLOAD CAPACITY AND DECREASED FUEL CONSUMPTION. THIS INTEGRATED IDEA OF TRANSPORT EFFICIENCY ALSO INCLUDES THE WORKSHOP AND SPARE PARTS SERVICE.

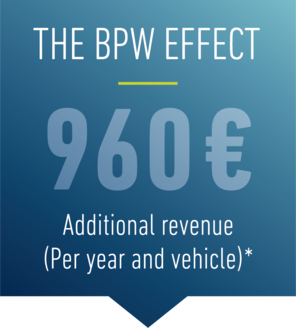

Seka Nutzfahrzeug GmbH has made a name for itself as a specialist for tank semi-trailers. This type of vehicle has an extremely long service life – up to 25 years is not uncommon. As a result, reliability and ease of maintenance have always been important criteria in the selection of running gear components. BPW has now combined these traditional quality characteristics with enhanced transport efficiency and a lightweight design – cutting the new running gear platform’s module weight to below 370 kilos for the first time. This translates into an additional annual turnover of 960 euros per tank semi-trailer and at the same time reduces CO2 emissions by 200 kilograms.

To achieve this, BPW has combined the tried-and-tested 9-ton Airlight II on-road air suspension with an aluminium hub and the new, even lighter ECO Disc trailer disc brake. In addition, an ultra-light trailing arm is now available for the first time that, thanks to an innovative manufacturing process, represents a major technological breakthrough – it is made of high-strength spring steel forged as a hollow profile modelled on nature.

In addition to Seka Nutzfahrzeug GmbH, Schmidt Fahrzeugbau GmbH also relies on the world’s lightest running gear – and combines it with BPW self-steer axles, if required. Based on the principle of a swivelling office chair or shopping trolley, they give the trailer unparalleled manoeuvrability. In addition, BPW has also been supplying an electro-hydraulic auxiliary steering system for reversing since 2018. This allows road tankers to be manoeuvred safely and precisely in confined spaces, such as at petrol stations or on farms. The self-steering axle also protects the tyres. BPW’s developers are focusing on tyres as the key to transport efficiency in a variety of ways. As such, the company was awarded the “European Transport Prize for Sustainability” for its AirSave tyre pressure control system introduced in 2019.

When transporting heating oil, hauliers can use the lightweight components to carry 96 kilos of additional payload – this corresponds to an extra 112 litres of heating oil that can be transported. With a fleet of ten vehicles that drive an average of 120,000 kilometres per year and have an average service life of four years, this means the company can generate over 38,000 euros in additional turnover. Furthermore, such a fleet would save more than 8,000 kilos in CO2 emissions.

»There are many factors that affect the profitability of trailers. The weight of the running gear plays an important role, but also its quality and ease of maintenance. This is why we opted for lightweight components from BPW such as the forged aluminium hub.«

Norbert Kempmann, Managing director of Kempmann Speditions GmbH & Co. KG

EFFICIENT AFTERMARKET

The BPW Group is also demonstrating how digitisation can transform an industry and create new benefits in the workshop and spare parts business – its fully automated spare parts warehouse upBox is being installed at an increasing number of workshops throughout Europe. After Finland, Lithuania and Germany, the solution will soon be offered in Sweden, Norway and Denmark. Whether in the form of a self-contained overseas shipping container in the yard (upBox Outdoor) or now also permanently integrated into the building (upBox Indoor), the upBox system automates the supply, replenishment and invoicing of spare parts. A growing number of workshops are also using the ability to identify and order spare parts via smartphone.

The BPW Aftermarket Group and PE Data are developing their database into an individual “digital vehicle file” that will enable workshops to carry out maintenance and repairs even more efficiently. It contains a history of previous repairs and will, in future, also be linked to the telematics system – meaning that the trailer will report its maintenance and repair requirements before components fail. Feasibility studies with customers and partners are already planned.

The BPW Aftermarket Group has, for the first time, permanently integrated its upBox technology into the workshop building. With this system, the technician is identified at the door via ID card and can then collect the required part. Reordering and billing are fully automated.