Transform Production

TRANSFORM

PRODUCTION

THE DESIGN, CONFIGURATION, ASSEMBLY AND MAINTENANCE OF TRAILER RUNNING GEAR FORM A DIGITISED LIFE CYCLE AT BPW. MANY VEHICLE MANUFACTURERS ARE ALREADY UTILISING THIS CONCEPT SUCCESS- FULLY – EACH IN A HIGHLY INDIVIDUAL WAY.

Hardly any other type of vehicle is as individual as the trailer – its design and manufacturing concepts have to meet requirements that are as varied as the goods it is used to transport. As a result, the trailer industry is highly specialised. BPW is committed to opening up new opportunities for vehicle manufacturers to configure and produce running gear more efficiently and at the same time more individually.

More than 100 users in the vehicle industry are already taking advantage of the ability to configure and order BPW running gear online. Thanks to the digital DNA of each individual part, it is possible to determine the ideal configuration with pinpoint accuracy. BPW has used customer feedback to make the configurator even more intuitive, and it now only takes a few mouse clicks to find the right running gear depending on the vehicle type, application and area of use – even without an engineering degree.

In future, further components from the BPW Group will be added, starting with support legs, turntables and mudguards. As a result, the configurator will become a comprehensive toolbox that can also perform brake calculations and the complete parameterisation of the vehicle. BPW will offer the system throughout Europe in 2020. Over the long term, the configurator can also integrate third-party products and grow into a cross-manufacturer platform.

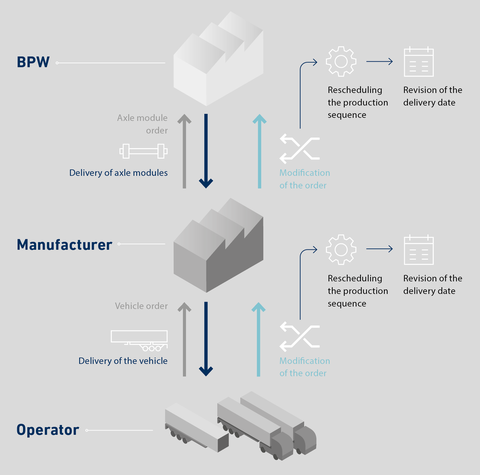

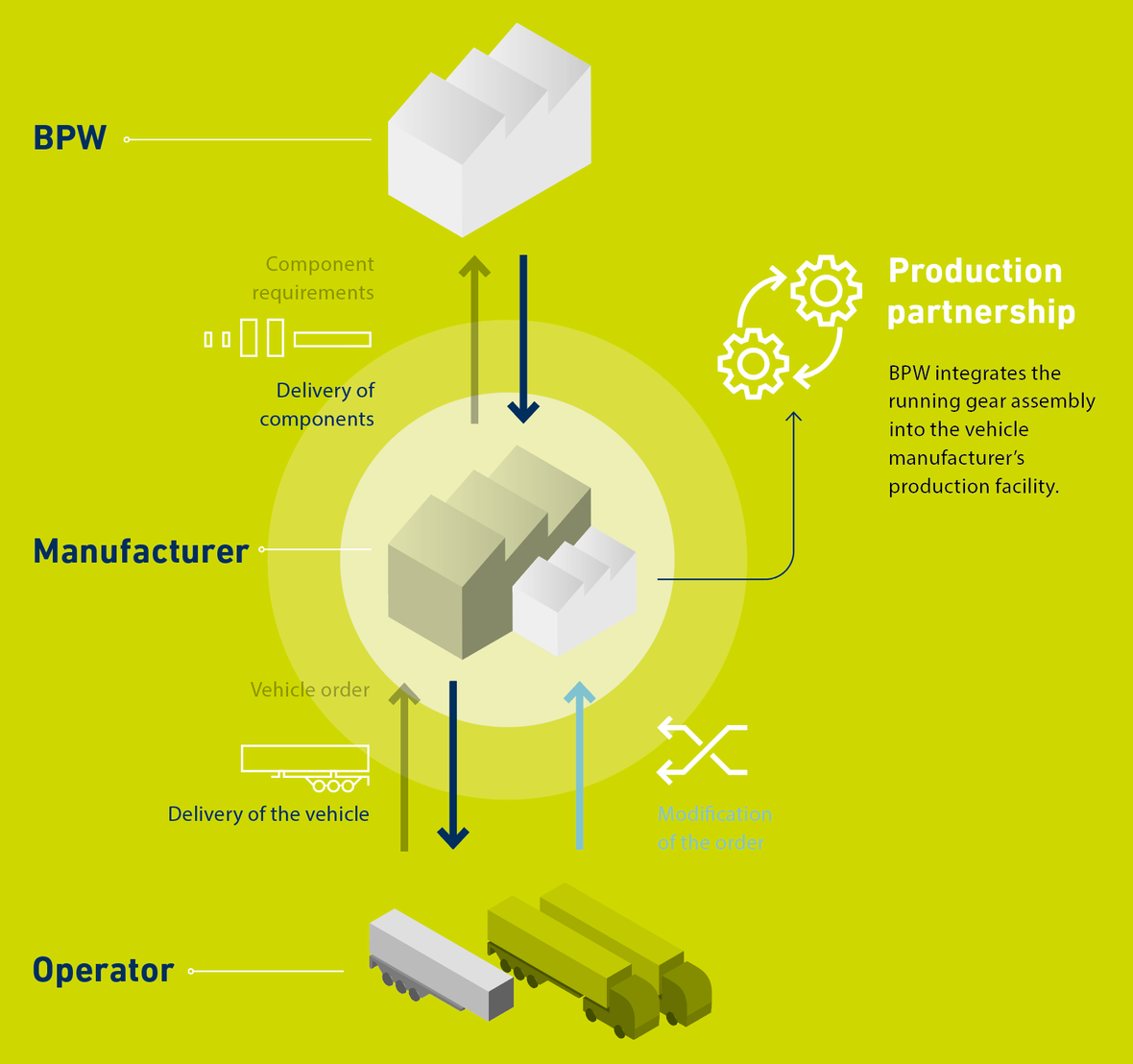

PRODUCTION PARTNERSHIP: BPW RUNNING GEAR – SEQUENTIAL OR ON SITE?

Most vehicle manufacturers precisely tailor the material flow to the production process. The downside to this approach is that if customer requirements change at short notice, the supply chain is thrown off track. Thanks to integrated running gear assembly with a future-orientated logistics concept, BPW now enables vehicle manufacturers to achieve a previously unknown degree of flexibility – the vehicle design can be changed on location, i.e. directly on site. At the same time, the production process becomes more robust and resistant to disruptions in the flow of goods, as is often currently the case during the coronavirus crisis but can also occur as a result of trade conflicts or Brexit.

AGRICULTURE AS THE AVANT-GARDE

BPW is also a driving force in the transformation of vehicle production in the agricultural sector. In this area, BPW helps manufacturers supply highly individualised vehicles. An intelligent modular concept combines the system advantages of standardisation with maximum adaptability – everything from the axle spacing, number of axles, wheelbase, width, driving height, tyre size, and drive systems can be changed. The idea of combining individual vehicle configuration with drastically simplified production processes is driving BPW to take this approach farther than any other company through its “FlexFrame” concept. Here, BPW delivers completely pre-assembled running gear directly to the vehicle manufacturer’s factory: axles, brake system, air suspension, steering systems, sensors and running gear computers – everything included.

Designing and manufacturing individual vehicles intelligently and economically is the mission that unites the engineers and sales professionals at BPW Agrar with their colleagues from BPW Sonderfahrzeugvertrieb. Since the technologies in these segments are increasingly converging, these employees have been combined into one team. Under the leadership of Peter Lindner, Director Sales, the Customised Solutions business unit consolidates the ideas, skills and passion of BPW’s experts for products developed to meet individual customers’ specific needs.